So far, so good: narrowed focus on fuel delivery = one if not THEE issue -

What we know:

Two identical pumps, each with a check valve are "Y'ed" together in a single feed line and will provide about 52 psi (static test conditions).

The problem came on suddenly. (This suggests something failing catastrophically - generally easier to find than something intermittent or insidious; a good thing, far as troubleshooting goes)

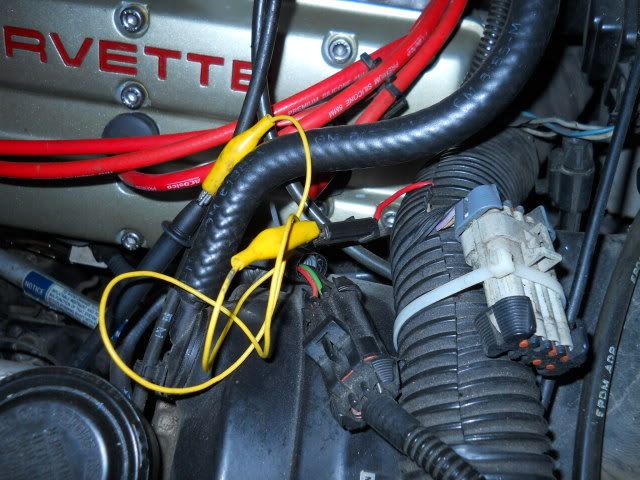

Jumping the battery to the fuel pump connector (ignition switch OFF) at least

ONE pump can be heard. (Both might be running, but

we don't know that. However, even with ONE pump continuously running, the pressure should be 50+, NOT 10. So, for now, we can set that aside move on. We can make a mental note to verify both pumps are running at a later time, if that becomes necessary.)

FP measured LOW at filter input.

Analysis so far:

Pressure is 10# at the filter input too. (This doesn't verify the filter isn't partially blocked, but is important to note perhaps for later, should it be necessary to test it)

Also, since there is no fuel flow in the line between the pressure gauge and the pumps, there will be

no pressure drop in the line,

even if there was a significant blockage. So... Again, another mental note: we haven't eliminated the possibility of a restriction in the line. However, we're tracking a pressure loss (not related to flow at this time). Time to go to the pump end and see what is going on.

Continuing troubleshooting...

Inspect the external connections at the pump for fuel leaks.

I would like to have known what the (test mode) current draw is with the test connector connected to the battery before we got to this point. But, no harm done if we do that now. Current draw in test mode in the 8-10A range would all but eliminate an electrical connection or grounding problem (but not totally eliminate the possibility...yes, another mental note to come back to, if necessary).

Pulling the pumps now will facilitate a COMPREHENSIVE visual inspection of the fuel pump assembly for anything mechanically impeding fuel delivery, e.g., a leaking hose or connection, or filter inlet blockage, etc (I actually found one of those red shop rags floating in my tank - apparently left and forgotten on a previous venture!)

Each pump has an internal check valve. If either valve is bad, that could be the problem. I found that even with mouth pressure* on the fuel outlet port, I was able to discover a bad check valve. (Note: I replaced my pumps a while back and one had a bad check valve

right out of the box.)

*A more scientific and accurate check valve test method can be accomplished by setting the pressure regulator on an air compressor to 50# and rigging up a hose and some clamps to pressurize the pumps' outlet to verify the check valve is working. If one is leaking, then isolate each pump and test.

I would suspect if you get this far, you'll have found the problem. But, IF NOT, then reinstalling the pumps and rigging up a jig to test fuel pressure at the pumps outlet feeding the fuel line is in order. And, if pressure is good there (you can even do a leak-down test too), then we can assume trouble between the inlet to the fuel line at the pump end and the fuel filter. Let's see whatcha come up with to this point, and get back to us...

BE VERY CAREFUL WHEN EXPOSING THE OPEN FUEL TANK!!! No flames, good ventilation, NO ELECTRICAL SWITCHES TURNED ON OR OFF, INCLUDING THE AUTOMATIC AIR COMPRESSOR SWITCH, OR ROOM THERMOSTAT SWITCH...

Good luck. Let us know...