|

|

#1 |

|

Join Date: Jul 2005

Location: SLOVENIA,EU

Posts: 126

|

Hi to all ,

Im going to eliminate secondarries with Haibeck prom - got vacum hadecke with this nassesary sistem....everything will go out  Will cruise control - tempomat , afer that still working? Thanks fo repy. Jano |

|

|

|

|

|

#2 |

Join Date: Feb 2010

Location: Pendleton, IN

Posts: 3,899

|

I doubt that you'll ever regret "ripping out" the secondaries.

I'm sure someone will answer your question shortly.

__________________

1988 KOH Prototype EX5023 sold 1990 ZR-1 #444 Convertible 1990 ZR-1 Black #966 1991 ZR-1 Quazar Blue #296 1957 Duntov SS Project Last edited by Blue Flame Restorations; 03-26-2013 at 04:02 PM. |

|

|

|

|

|

#3 | |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

Quote:

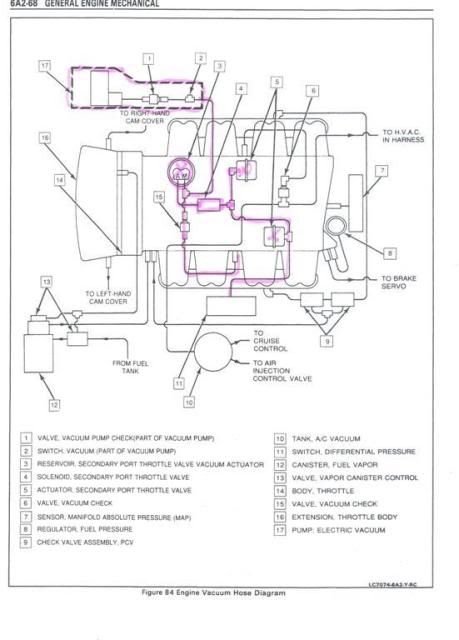

Everything in PINK comes out. As you can see, the vacuum port on the right side of the plenum supplies vacuum for the cruise and everything else.  Unless you have a "kit", you'll need some gaskets and some freeze plugs. I would assume Marc is going to round those up as a package and send it along with the prom, yes? If NO, then be sure to ask him for them, or PM me and we'll get it handled. Jerry...are you reading this? You know the gaskets he'll need, and also the freeze plugs (Dorman 555s, as I recall?). P. Last edited by Paul Workman; 03-26-2013 at 03:44 PM. |

|

|

|

|

|

|

#4 | |

Join Date: Jan 2009

Location: Portland Oregon metro area (Washington side)

Posts: 3,193

|

Quote:

__________________

Scott Vett owner since 1979._It's about the car and the people |

|

|

|

|

|

|

#5 | ||

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,817

|

Quote:

Quote:

See Vacuum Systems (Secondary and Cruize)

__________________

Clickable links On Iphone Touchable Links -Solutions- LT5 Modifications/Rebuild Tricks Low Mileage ZR-1 Restoration 1990 Corvette (L98) Modifications LT5 Eliminated Systems LT5 Added Systems LT5/ZR-1 Fluids 1995 LT5 SPECIFIC TOP END REBUILD TRICKS Last edited by Dynomite; 03-29-2013 at 10:25 AM. |

||

|

|

|

|

|

#6 |

Join Date: Feb 2010

Location: Pendleton, IN

Posts: 3,899

|

Woops..... Another KLUDGE!

__________________

1988 KOH Prototype EX5023 sold 1990 ZR-1 #444 Convertible 1990 ZR-1 Black #966 1991 ZR-1 Quazar Blue #296 1957 Duntov SS Project |

|

|

|

|

|

#7 |

Join Date: Sep 2012

Location: Rockwall, Tx

Posts: 1,504

|

Let's see. That means our hp per litre actually goes up!

__________________

_________________ 1994 AB/Grey #141 430 RWHP/392 RWTQ FBI Lyposuction / Secondaries relieved of duty / SW Long Tube Headers / Corsa Exhaust / FIC SS Injectors / MSD Coils / Lightweight Pulleys / Corey tuned B & M Shifter / Aluminum Flywheel / Samco Hoses / Shelby Series One's / C4 No Flex Frame Stiffener BBC - Bling By Carter: Custom ZR-1 Center Caps / Custom Plenum Plate / Air Box Knobs / TB Cover / Oil Filter Cover |

|

|

|

|

|

#8 |

Join Date: Jan 2009

Location: Portland Oregon metro area (Washington side)

Posts: 3,193

|

It's not a kludge if it's well documented and supportable. Just a LT4.9

__________________

Scott Vett owner since 1979._It's about the car and the people |

|

|

|

|

|

#9 |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

|

|

|

|

|

|

#10 |

Join Date: May 2007

Location: Peoria, AZ

Posts: 9,120

|

__________________

GOLDCYLON - 91 ZR-1 #2014 GOLDCYLON - 90 ZR-1 #2794, 4L60e (Formerly Schrade's) GOLDCYLON - 11 CTS-V Arizona State Director  91 WHITE/BLACK #2014. 380 P&P&PCed,Ported Heads, Jeal Long tubes, Corsa Exhaust/FIKSE FM-5s /LED TLs, LED Headlights, Front Wilwood 6 piston narrowlite calipers and rear Wilwood caliper street shop mod,CNCed Coolant Pipes,TPI Cvr,Filter cover,Stainless Bolts, DRM/DOM PROM /ZFDOC mod build #102,DRLs,BMAD with stainless Debris Screen,Coplan Air Blaster, Pioneer APP Radio 4,Brey-Krause HB,Sub Bar,Fire extinguisher seat mount,DRM Coilovers,LEDs everywhere,Compass mirror (orange),V1 DIC hidden display, Homelink sun visor, Carbon Fiber top x3 and APSIS Carbon Fiber interior, APSIS CF Steering Wheel/NAPA Leather, Banski trailing arms, Guldstrand front suspension,urethane bushings from Prothane (total suspension) ZFDoc drive shaft safety loop, raptor shift light (orange),AO engineering louver front plate, Console seat cushion, 96CE seats with black custom Sheepskins, ss billet catch can,Viper remote entry/alarm,Cragar Rear Louvers,LED side louver lights, Dewitts Radiator with SPAL fans and a Woods 160 T-Stat 90 RED/BLACK #2794. 4L60e Automatic Stage V by RPM Transmission, TCI Dedicated TCM, OBX Stainless Headers, Corsa Exhaust, SAN Secondaries and Haibeck PROM, Exotic Muscle Coil overs, LED Interior Lights, LED Tail Lights, LED Headlights, 94 Sport seats with black custom Sheepskins , Cragar rear louvers, GS Front calipers, Banski Trailing arms, APSIS Carbon Fiber steering wheel, Front and Rear Baer Eradispeeds, DRLs, Guldstrand front suspension,urethane bushings from Prothane (total suspension), Dewitt's Raditor with Dual SPAL fans and a Haibeck 170 T-Stat 11 RED/GREY CTS-V |

|

|

|

|

| Thread Tools | |

| Display Modes | |

|

|