|

|

#11 |

|

Join Date: May 2005

Location: Leesburg, VA

Posts: 2,713

|

I did not use anything on the gasket. Though in retrospect some gasket adhesive or something would have made it a lot easier. Without help, it's tricky to lift the pan, keep it flush, and not knock the gasket off, all while threading in a couple bolts.

__________________

Bob Saveland Former owner of #2517 [IMG]http://a.random-image.net/aurora40/vette.jpg[/img] |

|

|

|

|

|

#12 | |

|

Guest

Posts: n/a

|

Quote:

Make sure you have a pop rivet gun to replace them after installing the new weatherstrip. Also take your time, if you bend them you will never ever get them straight again. |

|

|

|

|

#13 | |

Join Date: Aug 2006

Location: McLean, VA

Posts: 3,702

|

Quote:

|

|

|

|

|

|

|

#14 |

Join Date: Dec 2004

Location: Jacksonville, FL USA

Posts: 4,645

|

just another fwiw suggestion on keeping the pan gasket from sliding around.

I bought this tube of gasket rtv by permatex. The stuff is like a big lipstick tube and it is handy for tracing the gasket with sealer so you can stick the gasket to a surface. It's non-hardening and it even allows the parts to come apart easily without ruining the gasket material....most of the time. I used it when i did my plenum pull to hold the gaskets in place while I put the I/H's on the head and the plenum on the I/H's. It worked great with only about 10 mins of set up time the gaskets didn't move much at all, and when I did miss I could slide the gasket sideways without any trouble at all. A thin film, almost transparent, did the trick I found. I was thinking about using dielectric till I saw this at the permatex display along with all the thread-locking liquids and the standard rtv's toothpaste tubes. I got it at the local auto zone store, but my guess would be any auto parts store has the same display.  Tom

__________________

1990 ZR-1, Black/grey, #2233, stock. ZR-1 Net Reg Founding Member #316 & NCM member |

|

|

|

|

|

#15 | |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,788

|

Quote:

Jerry's pan gasket for the 90'-92' requires a new "O" ring which is the same diameter but thicker for the oil pick up. Just make sure you keep that "O" ring in place as you position the oil pan with new gasket. I use Blue Loctite on ALL Oil Pan Bolts. Last edited by Dynomite; 09-06-2013 at 11:16 PM. |

|

|

|

|

|

|

#16 |

Join Date: Aug 2006

Location: McLean, VA

Posts: 3,702

|

Thanks guys. I will use some Permatex.

|

|

|

|

|

|

#17 | |

|

Guest

Posts: n/a

|

Quote:

He has a later motor, which has no pick up tube O-ring. You haven't been paying attention on my tear downs |

|

|

|

|

#18 | |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,788

|

Quote:

Too much attention to Corvette Babes and Avatars and not enough attention to Z mechanics  When I get all your advice and tear downs documented into WORD documents (including a search of the archives for your great advice) I will sell that information as Z Supplemental manuals on Ebay Last edited by Dynomite; 02-25-2010 at 04:41 PM. |

|

|

|

|

|

|

#19 | |

Join Date: Dec 2003

Location: Arcadia,OK

Posts: 3,372

|

Quote:

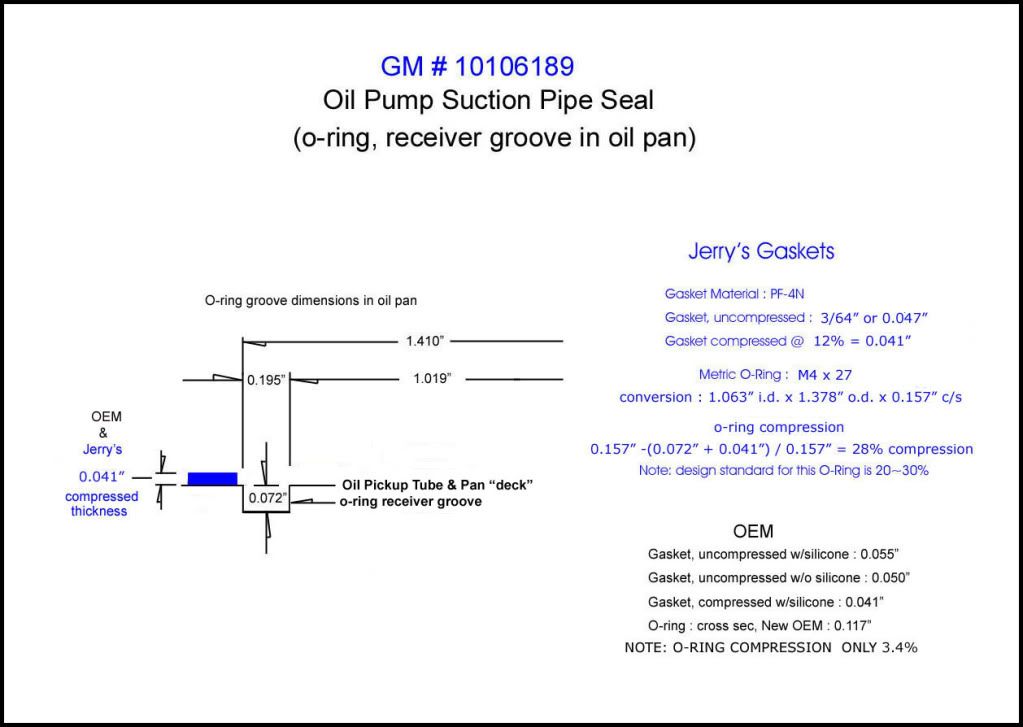

The OEM o-ring when used with the OEM pan gasket or mine, is only compressed 3~4%, whereas design standards for o-rings of this size & used in flange seal applications is significantly higher at 20~30%. Here's a drawing to show the application details. Post any questions you have & I'll do my best to answer. BTW, the drawing shows the o-ring groove to be in the pan, whereas it is actually in the oil pickup tube, which is at the same level as the oil pan.

__________________

Jerry Downey JERRYS LT5 GASKETS & PARTS http://www.jerrysgaskets.com 1994 ZR-1, Black/Black, Lingenfelter Aerobody, 416cu in, 3.91 gears, coil-over susp, Brembo brakes, etc. 2016 Black-Red, 3LT-Z51 Auto 8-speed. Last edited by A26B; 02-25-2010 at 01:09 PM. |

|

|

|

|

|

|

#20 | |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,788

|

Quote:

I measured an OEM used gasket after removal and found .047 which is exacltly what Jerry suggested for an uncompressed OEM gasket. This is the second time in this thread I have been appropriately corrected I am going back to the Corvette Babes section and resign myself to commenting on Avatars from now on  Say......after visiting the Corvette Babes section, studying Jeff's Avatar again and doing some more thinking........are you saying that your "O" ring (oil pickup for 91' Z) is thicker than OEM with greater compression and resulting greater sealing? If so....my perception is not completely off the mark and I prolly will take back my statement regarding my commenting on Corvette Babes and Avatars only

Last edited by Dynomite; 06-25-2012 at 06:32 PM. |

|

|

|

|

|

|

|