|

|

#1 |

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

"Power under the curve" is often quoted, but my expertise (if I have any) is in electronics - which like mechanical engineering is also based in physics. But, I hesitate to transfer any established power treatments to this mechanical application w/o some guidance from someone with some MECH. ENG background. And, then again, there is a favorite axiom: "Watts is watts".

Watts is a quantity I'm familiar with, and "watts" is used a lot in Europe to quantify (engine output) power; and of course there is a simple conversion factor for watts to HP. I feel like I'm staring right at the answer, but hesitant to jump w/o some guidance/expertise! A simple way to calculate "power under the curve" is what I'm after. Marc? Todd? Corry? Jerry? Anybody? Last edited by Paul Workman; 06-15-2015 at 09:34 AM. |

|

|

|

|

|

#2 |

Join Date: Feb 2011

Location: San Marcos CA

Posts: 1,786

|

My comment on the subject is going to touch upon intangibles like an engines willingness to change rpm (rate of change of acceleration- jerk and so forth) and its peakiness or how long does the torque stay high before it nosedives like a truck engine.

You can boost a turbo diesel to impressive torques which will push some of these trucks down the road pretty fast on the roll, but in the lower gears the sweet spot is so short that it seems like you spend more time shifting. That and the flywheels and internals are so heavy (for their intended purpose which is not racing) that they just seem like a lumbering brute force way to get the job done. My conclusion is that transmissions and gearing has helped modern performance more than the engines, but the use of variable valve timing technology has been nearly as big a leap in powertrain tech. |

|

|

|

|

|

#3 | |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

Quote:

|

|

|

|

|

|

|

#4 | |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,817

|

Quote:

Tech Info - LT5 Horsepower and Torque Calculations Tech Info - ZR1 Differential Gearing and Vehicle Speed Calculations Tech Info - ZR1 Wind Force, Rolling Resistance, Drivetrain Loss Calculations Tech Info - L98 Frisbee Horsepower Now if you have high torque throughout the RPM range you will have more power under the curve Torque is related to Displacement........so more power under the curve can be had by increasing Displacement. Using Calculas we would have the ingegral of Torque over the RPM range to get the Area Under The Torque Curve. Actually I think it is the integral of Horsepower over the RPM range to get Total Power Under the Horsepower Curve. How to calculate Area under the Horsepower or Torque Curve Calculas is the slicing of RPM to extremely thin slices and multiplying by the Horsepower of each incremental slice of RPM for an incremental Area, Then adding up all the incremental Areas of each incremental slice of RPMxHorsepower. Something like the Integral of HP drpm (integral of rpm) from rpm of zero to maximum rpm. Where your gear ratios are variable over a broad range of RPM such as on the street......your performance will be better with a lot of Horsepower Under the Curve vice having higher Peak Horsepower at a narrow range of RPM. Where your operation is in a narrow RPM range at Peak Horsepower your Horsepower under the curve may be less but your 1/4 mile time much better.

__________________

Clickable links On Iphone Touchable Links -Solutions- LT5 Modifications/Rebuild Tricks Low Mileage ZR-1 Restoration 1990 Corvette (L98) Modifications LT5 Eliminated Systems LT5 Added Systems LT5/ZR-1 Fluids 1995 LT5 SPECIFIC TOP END REBUILD TRICKS Last edited by Dynomite; 06-15-2015 at 11:29 AM. |

|

|

|

|

|

|

#5 |

Join Date: Feb 2011

Location: San Marcos CA

Posts: 1,786

|

^^^ That's what all these close ratio transmissions in newer cars are all about- integrating to find the best part of the hp curve and staying in a narrow zone or the 'sweet spot'. Is it cheating when you can change where the intake valve closes? That will extend the power curve a lot too. Most LS engines didn't have that feature so they just made them all over 6 liters of displacement to meet the performance goals.

I remember the first 5 speed automatic I ever drove (a Ford explorer)- I was so impressed how it zero-to-sixty'd by only dropping about 400 rpm from 1st, second, and third gear. |

|

|

|

|

|

#6 |

Join Date: Dec 2003

Posts: 482

|

If I wanted to calculate the area under a HP or torque curve, calculus is not going to help me other than to better understand the theory. I do not have an equation for the inital curve to begin with. So I would just photocopy the curves onto a sheet of graph paper and count squares. Perfectly legitimate answer, if not very brainy. Fancy way would be to weigh a full sheet of paper, cut out the area under the curve and then reweigh. Ratio out the area from the change in weight. George

|

|

|

|

|

|

#7 | ||||

Join Date: Nov 2007

Location: Squires (near Ava MO in the Mark Twain N'tl Forest) - Missouri

Posts: 6,466

|

Great thoughts, gents! I feel like we're nibbling around the edges - "touching the (creek) bottom", so to speak - which feels good so far.

Quote:

(Hello, Cliff! I'm glad you joined the fray - didn't mean to exclude you (the Registry's Archivist especially)! (Hello, Cliff! I'm glad you joined the fray - didn't mean to exclude you (the Registry's Archivist especially)!Well, kidding aside (for now) maybe I should 'chunk this up' into bite-size pieces... As suspected, w/o a formula that provides either horsepower (hp) or torque (tq) curves, calculus isn't going to work for a variety of reason, but especially when there are infinite variations of tq & hp values (curves)/RPM among the potential variety of (engines) being analyzed. More on this later, but Mike makes an observation which may be "spot-on" and applies directly to our discussion - Quote:

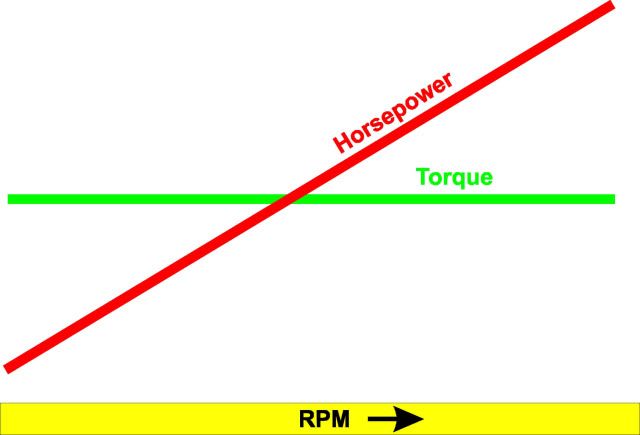

Note: An example of optimizing a very narrow peak power-rpm band is the close-ratio gearbox used in semi-tractor/trailer (big) rigs: sometimes 18+ forward combination of transmission and differential gear ratios designed to keep the maximum power at the wheels. Another example is the paddle shifted transmissions of the high-winding MP1 cars (e.g., that just ran the 24 hour LeMans). Inside the cockpit video shows clearly how narrow the ratios are between gears, and how close the rpm range is maintained. The question becomes: "What about the torque reduction at the wheels resulting from shifting to a higher gear? Isn't the reduction in torque an issue?" All things being equal, the classic answer would be: "Watts is watts", right? After all, the gear box is just swapping less torque for greater speed; (torque x speed = power), and decreasing tq with a proportional increase in speed means no loss in power to the wheels, right? Not so fast... Here's the nut of this whole exercise: suppose we're comparing two engines which operate across significantly different RPM ranges? For clarity, let's us assume two motors with flat tq curves across their rpm limit (below):  Now, suppose we've got one motor that operates with the same torque output across twice the RPM range limit of the other motor: to optimize (race) performance, at what rpm would we shift them, respectively, keeping in mind...watts is watts?? SO! It seems pretty clear that IF torque of two motors is equal across their respective RPM limits, the one with the higher rpm range would have greater power generating potential. But, carrying it a step further, suppose the torque of the motor with the narrower rpm range was to be higher than that of the other motor that operates across a wider rpm range? Well, again its power: "watts is watts"*, and the motor generating the most power (watts or horsepower [i.e., 745.7 watts/hp]) will out perform the lesser power source. Now...we start getting into the weeds, when we acknowledge the power curves are NOT flat across the rpm range, and the rpm range may differ significantly between two motors we might want to compare! Dynomite and Corvettes White I believe may be on the trail, albeit coming from slightly different angles, but I (for one) am going to have to chew on it a bit more: This link puts some light on how Excel might be used to answer the power question - at least for motors operating w/in the same RPM limits. Quote:

Quote:

I feel I'm seeing light at the end of the tunnel. I just hope...(you know what!!) |

||||

|

|

|

|

|

#8 | |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,817

|

Quote:

And Forum Archivist is kind of wussy sounding like I am a librarian or something (but a librarian who drives a Z is cool)  On the "Other Forum" I am a "Technical Contributor"  Lets see.......that about does it.....say Paul....I am installing my third Ron Davis Radiator tomorrow in what was suppose to be my Stock 1990 in CA.....did the same to what was suppose to be my Stock 1990 in SD. I will take the 1990 for a run when it is 100 deg ambient today with stock radiator and then another run tomorrow in 100 deg ambient with the Ron Davis. Including idling as in sitting at a stop light for both (Stock and Ron Davis) with air on and off to see what maximum coolant temperatures are like for both Stock and Ron Davis. This testing with the same identical AC Condenser, Same identical Oil Cooler, Same Identical Coolant Fans and same identical 180 deg Thermostat. If you want to test radiators....this is the time  Jun 16 Hot with plenty of sunshine 98°Lo 61° Jun 17 Blazing sunshine and hot 101°Lo 63° more Jun 18 Blazing sunshine and hot 101°Lo 62° more Jun 19 Hot with plenty of sunshine 100°Lo 64° more Jun 20 Hot with blazing sunshine 103°Lo 66° more

__________________

Clickable links On Iphone Touchable Links -Solutions- LT5 Modifications/Rebuild Tricks Low Mileage ZR-1 Restoration 1990 Corvette (L98) Modifications LT5 Eliminated Systems LT5 Added Systems LT5/ZR-1 Fluids 1995 LT5 SPECIFIC TOP END REBUILD TRICKS Last edited by Dynomite; 06-16-2015 at 11:32 AM. |

|

|

|

|

|

|

#9 |

|

Join Date: May 2007

Location: Chicagoland, IL

Posts: 9,686

|

With both fans running, my Fluidyne is keeping coolant temps at 90C at idle in 95F weather.

|

|

|

|

|

|

#10 | |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,817

|

Quote:

Ron Davis yesterday in a 1991 Z keeping 87C cruising and 97C idling at stop light AC on 95 deg ambient. This using the Digital readout of Fan Controls. More on the Before and After Ron Davis this week in 100 deg F ambient. I will try that excuse when stopped by CHP....."I was testing my radiators".....or better yet...."But Officer...I was just trying to see the effects of Power Under The Curve" to get this back on track See LT5 Cooling and Radiators

__________________

Clickable links On Iphone Touchable Links -Solutions- LT5 Modifications/Rebuild Tricks Low Mileage ZR-1 Restoration 1990 Corvette (L98) Modifications LT5 Eliminated Systems LT5 Added Systems LT5/ZR-1 Fluids 1995 LT5 SPECIFIC TOP END REBUILD TRICKS Last edited by Dynomite; 06-16-2015 at 11:48 AM. |

|

|

|

|

|

|

|