|

|

#1 |

Join Date: Dec 2019

Location: Indianapolis, IN

Posts: 45

|

Hello - looking for some advice on clutch and flywheel replacement on my 90 Z. My current pilot bearing began making noise last week and has gotten worse, so I'm now forced to take everything apart. Car currently has a Carolina Clutch single mass flywheel/pressure plate combo. I have parts for converting back to a dual mass setup (flywheel and oem lt5 pressure plate). Going off of Marc's article for clutch replacement with a dual mass, I've purchased the centerforce clutch disc (with shims) he recommends as well as the Acdelco roller pilot bearing.

So questions I'm trying to get answered before taking everything apart: 1. Is there a recommended throwout bearing for an oem setup? I've found this - does anyone have experience using? HTML Code:

https://www.summitracing.com/parts/ctf-n1400/all 3. Current parts list: dm flywheel, oem pp, clutch disc, shims for centerforce disc, pilot bearing, slave cylinder, new fluid, TO bearing (above), pp bolts (above). Am I missing anything? 4. Plan on installing the rear diff drain plug (& fluid swap) while exhaust is off as well as replacing the clutch slave cylinder. Any other things to check/change while everything is apart? 5. Any other tips/tricks I should keep in mind or know for making this swap? Thanks in advance!

__________________

'90 #413 Red/Red Sold '90 #1583 Red/Red

|

|

|

|

|

|

#2 |

|

Join Date: Apr 2020

Location: Ridgecrest ca

Posts: 70

|

Best thing to do is contact zfdoc . He is awesome at figuring clutch problems out 602 319 6575

|

|

|

|

|

|

#3 | |

Join Date: Dec 2003

Location: Arcadia, OK

Posts: 3,401

|

Quote:

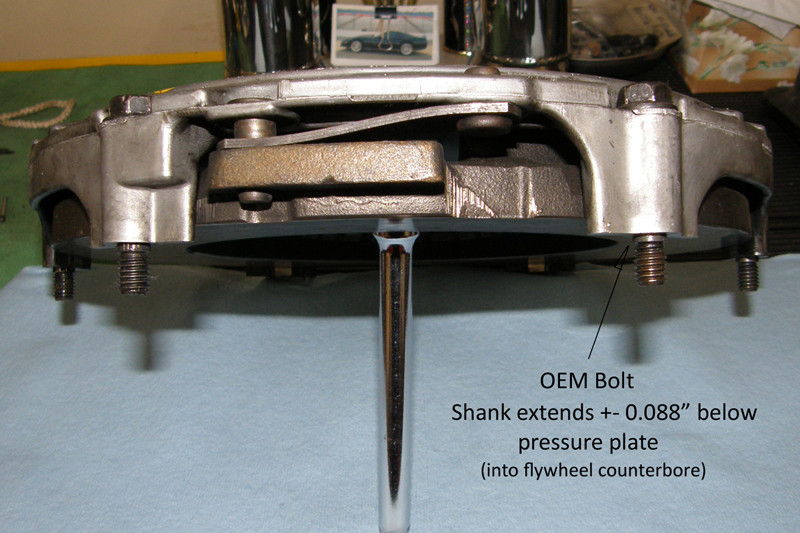

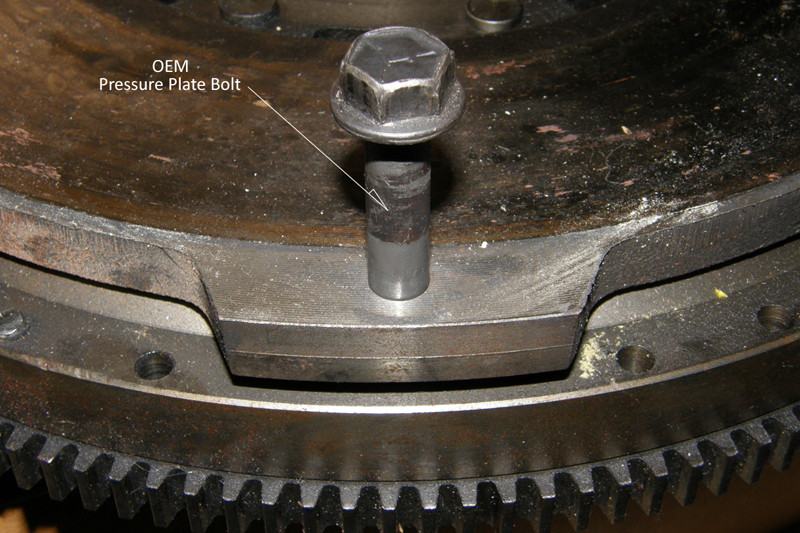

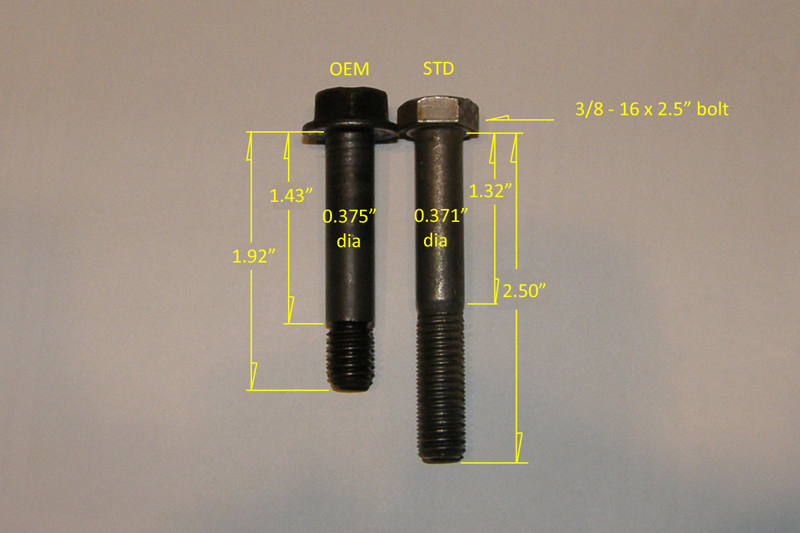

The following photos show how the OE Pressure Plate bolts engage the flywheel to provide maximum shear resistance and whereas a typical bolt does not. Photo 01  Note the full diameter shank extends below the pressure plate and ultimately into a close tolerance counterbore in the flywheel. Photo 02  The counterbore in the flywheel is abt 0.150" deep, which receives the 0.375" diameter x 0.088" bolt shank. The purpose is to provide maximum shear resistance, which a standard bolt will not do. Photo 03  Correct Pressure Plate bolt installed in the flywheel to demonstrate correct fitment. Photo 04  Demonstrates how a standard bolt cannot provide equal shear resistance, due to two, primary reasons. (1) the root of a typical 60 deg, V thread is 22% less in diameter and 38.5% less cross sectional area than the 0.375" OE bolt (2) A typical bolt thread will have a sharp bottom at the thread root, i.e. a stress riser, the origin point of breaks. Photo 05  Comparison of the OE Pressure Plate Bolt to a standard bolt. The grade of the bolt, 3, 5, or 8, all have the same thread form. The critical dimensions are the shank diameter & length, both lacking in the standard bolt. Cutting the bolt off to the proper length, still leaves exposed threads above the surface of the flywheel.

__________________

Jerry Downey JERRYS LT5 GASKETS & PARTS http://www.jerrysgaskets.com 1994 ZR-1, Black/Black, Lingenfelter Aerobody, 416cu in, 3.91 gears, coil-over susp, Brembo brakes, etc. 2016 Black-Red, 3LT-Z51 Auto 8-speed. Last edited by A26B; 03-20-2021 at 09:29 PM. |

|

|

|

|

|

|

#4 | |

Join Date: Aug 2009

Location: South Dakota/California

Posts: 3,816

|

Quote:

__________________

Clickable links On Iphone Touchable Links -Solutions- LT5 Modifications/Rebuild Tricks Low Mileage ZR-1 Restoration 1990 Corvette (L98) Modifications LT5 Eliminated Systems LT5 Added Systems LT5/ZR-1 Fluids 1995 LT5 SPECIFIC TOP END REBUILD TRICKS Last edited by Dynomite; 03-20-2021 at 04:01 PM. |

|

|

|

|

|

|

#5 |

Join Date: Jan 2004

Location: Enterprise, Alabama

Posts: 356

|

Quote----I've found this - does anyone have experience using?

HTML Code:

https://www.summitracing.com/parts/ctf-n1400/all Thanks in advance![/QUOTE] Just put that TB from Summit in my Z. Good product, it will make a noise just spinning it by hand and the center will look not centric. This is normal and it functions perfect. I use Power torque brand from Oreily's (Master and Slave unit) with good results. Good construction.

__________________

Tony Davila (Projects) Water Meth: http://www.zr1.net/forum/showthread.php?t=19422 Exhaust cut outs: http://www.zr1.net/forum/showthread.php?t=22689 Auxiliary 12V install: http://www.zr1.net/forum/showthread.php?t=22878 Auxiliary pusher fan install: http://www.zr1.net/forum/showthread.php?t=22859 Oil Catch can Project: http://www.zr1.net/forum/showthread.php?t=20320 |

|

|

|

|

|

|